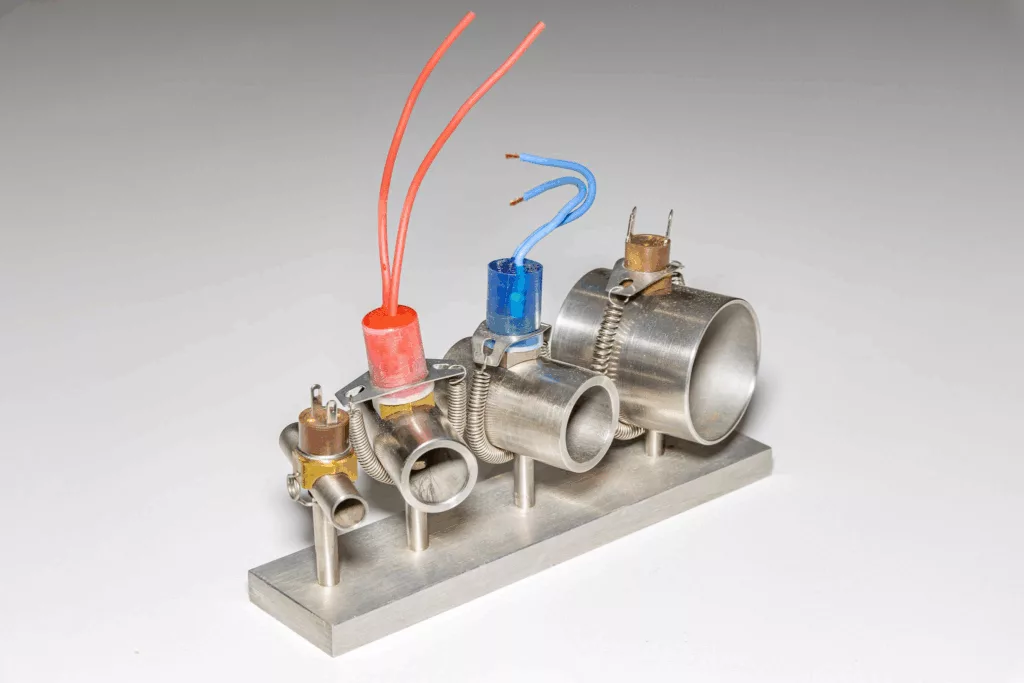

In industrial, defense, aerospace, and other demanding environments, component reliability is crucial. When it comes to managing weak signals or low-intensity loads, the choice of contact materials plays a decisive role in long-term performance. In this context, the gold-contact bimetallic thermostat stands out by meeting high precision and performance requirements.

Reliability for Low Currents

Thermostats with gold-plated contacts ensure excellent conductivity, especially at very low currents—sometimes in the milliampere range. Unlike standard contacts, which may cause signal loss or unreliable connections at such levels, gold contacts guarantee consistent and secure signal transmission.

This type of component is highly recommended for sensitive equipment used in demanding environments. Gold offers a clear advantage here: it maintains a stable contact point without oxidation or loss of performance over time, with no need for maintenance cycles.

In contrast, silver contacts naturally wear over time, leading to the formation of a thin oxidation layer. In low-current circuits, this layer can be enough to block the signal entirely, causing malfunctions or unexpected interruptions.

Exceptional Resistance to Oxidation

One of the major benefits of gold contacts lies in their chemical composition. Gold does not oxidize or sulfate, even in harsh or polluted environments. Contacts retain their effectiveness even after long periods of inactivity. This ensures immediate electrical continuity upon activation, without requiring prior cleaning. This property is critical in sensitive applications like medical devices or security systems, where even a minor contact failure can have serious consequences.

Gold Contacts – Ideal for Short, Fast, and Frequent Cycles

Modern applications often require components capable of withstanding very frequent activation cycles under low loads. Gold contacts are perfectly suited for such use: they resist micro-arcs generated by low loads while avoiding premature wear that other contact types may suffer.

Thanks to their low contact resistance, they also ensure a very stable contact voltage, which is essential to prevent voltage drops or signal loss. This results in an extended equipment lifespan—up to 10 times longer than that of silver contacts, even in the most demanding applications.

Conclusion

While gold-plated contacts offer undeniable advantages in terms of reliability for low currents, oxidation resistance, and lifespan under frequent cycles, they are not always the universal solution.

Silver contacts, which are more economical, are better suited for higher loads and high-current applications, where their excellent conductivity can be fully leveraged. However, they are more prone to oxidation and pollution, which can be problematic in control circuits or intermittent use cases. Therefore, the choice between gold and silver contacts should be based on your specific application requirements: type of current, usage frequency, environment, and expected safety level.

Need technical advice or a quote ?

At Heito, we support our clients in defining the most suitable thermal solution for their needs—whether gold contacts for low signals or silver contacts for higher loads. Our expertise ensures you get a reliable, durable component that matches your application.

FRANçAIS

FRANçAIS DEUTSCH

DEUTSCH